The Vertical Glass Washing Machine “ProWASH” represents a technological evolution of our product line, designed to meet the needs of small and medium glassworks aiming for larger-scale projects. Our solution is designed to adapt to a wide range of processing processes, including glass cutting, grinding, bevelling, drilling, CNC machining, tempering, molding, and painting, offering superior performance for glass cleaning and drying.

The most automated version the ProWASH is equipped with devices for measuring glass thickness and adjusting the positioning of brushes and blowers, allowing the washing of glass thicknesses from 3 mm up to 25 mm. Its electromechanical glass thickness opening can be operated manually by the operator or automatically, providing greater flexibility.

The washing machine consists of an inlet/outlet conveyor and a washing station with drying, mounted on a monocoque frame in painted steel, with a stainless steel base, roof, and interior. The washing group with six brushes (Ø150mm), equipped with special bristles, ensures consistent performance on every type of glass, including delicate ones like low-emissivity (low-e) glasses. The three water recycling tanks, complete with pumps and filters, allow efficient use of water resources and maintain a high standard of cleanliness.

One of the distinctive features of the ProWASH is the presence of tall drive shafts, which ensure greater contact with the glass and greater traction safety, ensuring a more stable and reliable production. Additionally, separate transmission systems between washing and drying reduce glass stops near the air blades and ensure a more linear and continuous production even in the presence of large glass panels.The washing process is divided into several phases: the first brush washes the glass with special rinse jets and hot water to remove surface debris and reduce contamination of subsequent brushes. During washing, sprayers with an innovative nozzle distribute water evenly, reducing waste and the risk of glass damage. In the chamber of the third brush, double sprayers are present to rinse the glass after washing. All three tanks can be connected independently to a reverse osmosis system. Finally, the drying area is equipped with angled air blades powered by a high-pressure fan, insulated to reduce noise emission.

Management of the washing machine functions, such as the rotation speed of the traction rollers, brushes, and fan rotation, is conveniently done through a PLC and a touchscreen display. Easy to clean, maintain, and replace, every component of the washing machine is designed to withstand the most demanding working conditions. Transmissions and mechanical components have been moved to the top of the machine, reducing the risk of contact with water and moisture and increasing the life of the installation. All controls available to the operator operate at low voltage and are equipped with protections compliant with European regulations to prevent access to hazardous parts of the machine. Our machinery complies with CE certification.

An automatic glass thickness detection system installed at the entrance of the washer to optimize washing and drying parameters for glass.

QUALITY CONTROL’1“LED LIGHTS”Addition of LED lights on the outlet conveyor for quality control.

QUALITY CONTROL’2“SCANNER”Addition of a conveyor with Glass Scanner built in for quality control of washed glass.

STRUCTURAL SOLIDITY STAINLESS STEELComplete restyling using stainless steel for the entire structure, both internal and external. This modification ensures corrosion resistance and durability over time.

DEMINERALIZED WATERAddition of a 150-liter reverse osmosis demineralizer.

INCREASED PRODUCTIVITYAddition of a traction motor on the outlet conveyor of the washing machine, to speed up the transfer of already washed glasses.

SPACE OPTIMIZATIONStructure redesigned with fan placed on top of the machine, leaving the passage behind the machine free.

12″ INCH MONITORInstallation with a floor console and an expanded 12-inch monitor to allow easier viewing of the production list.

GLASS SUPPORT WHEELSSupport wheels for slabs/glass made of plastic material with assembled polyurethane ring.

HORIZONTAL CONVEYORAddition of one or more horizontal conveyors to adapt the machine to other processing lines.

TILTING CONVEYORAddition of a tilting conveyor/roller conveyor to adapt to various needs.

ROTATING CORNER CONVEYORThe 90° rotating corner conveyor can be installed both before the machine inlet conveyor and after the outlet conveyor. Its standard length is 3500 mm. It requires a space of 4000 mm x 4000 mm. Allows rotation (0°-90°) of glass up to 3500 mm in length Enables the integration of new machines into the production line even if space in the building would not allow it

ADDITIONAL CONVEYORThe additional conveyor can be positioned both before the machine inlet conveyor and after the outlet conveyor. It occupies no more depth than the machine itself. Allows processing of glass up to 6000 mm in length After the outlet conveyor, with 2 motors, it becomes a storage zone for smaller glass sizes

| Minimum Glass Size: | W400 mm x H200 mm |

| Maximum Glass Size: | W3000 mm x H2000 H2500 mm (variable length upon request) |

| Glass Thickness: | 3 mm – 25 mm |

| Transportation System: | rubber/polyurethane rollers |

| Transportation speed: | max. 6 meters per minute (from 2 to 6 meters per minute) |

| Brushes: | 6 brushes Ø150 for low-emissivity (Low-E) |

| Tanks & Pumps: | N°3 independent tanks each with N°1 pump |

| Compressed Air: | 6 bar – 1/2 |

| Blowers: | N°2 air blades |

| Fans: | N°1 high-pressure fan on insulated box |

| Filtration System: | N°1 filter for each tank |

| Operator Interface: | touch screen panel with remote connection |

| Power Supply: | 400 V – 50Hz 3Ph + Ground + Neutral |

| Maximum Load: | 120Kg |

| Glass Transport Height: | 650 mm (+/-50mm) (variable height based on requirements) |

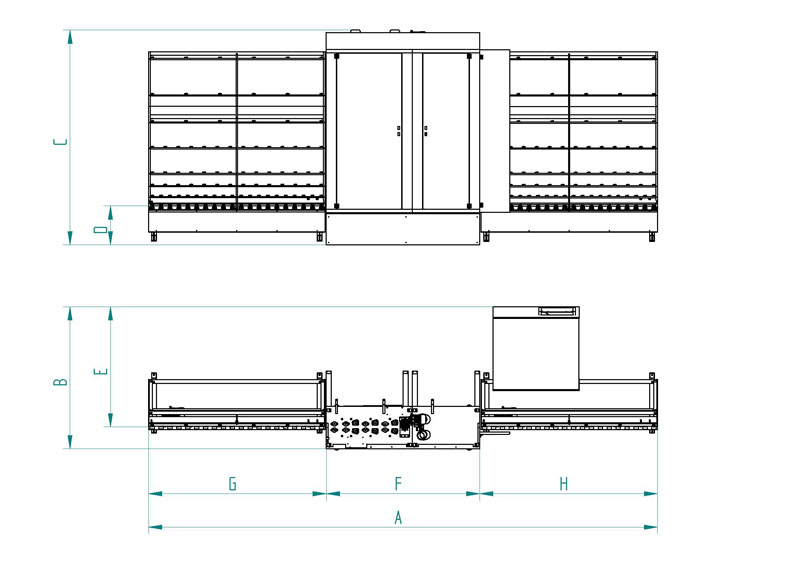

| DIMENSIONS | A | B | C | D | E | F | G | H |

| H1600 | 8400 | 2380 | 2670 | 600 | 1980 | 2500 | 2950 | 2950 |

| H2000 | 8400 | 2380 | 3070 | 600 | 1980 | 2500 | 2950 | 2950 |

| H2500 | 8400 | 2380 | 3570 | 600 | 1980 | 2500 | 2950 | 2950 |

Copyright © 2023 Itech Srl – C.F. and P.IVA 03587980289 – R.E.A. of PD 321966 – C.S. Euro 25,500.00 i.v.