The IT115C Motorized Two-Blade Spacer Cutting Machine represents a compact and highly efficient solution specifically designed to meet the needs of insulated glass production. This innovative machine can cut a wide range of spacers, including aluminum, steel, stainless steel, steel-plastic, and plastic profiles. Conceptually built as a simplified workstation, the machine consists of a central body for cutting and milling the spacers, flanked by two horizontal arms. The length of the horizontal arms can be customized according to specific cutting requirements. Two cutting blades, one for steel and the other for aluminum/plastic, operate pneumatically to allow continuous and efficient operation, reducing the need to change the blade. The rotation and cutting speed are adjusted via a touch screen, optimizing operational efficiency and allowing the management of multiple tasks with a single machine, reducing factory footprint and ensuring uniform production.

The profile cutter features a positioning axis driven by a brushless motor, ensuring rapid and precise movement. A blade blow-off system with oil ensures the cleanliness and lubrication of the blades during cutting. The touch screen operator interface enables remote connection and displays the piece counter to monitor production. A distinctive feature of our machine is the large-sized clamping vise, which allows the simultaneous cutting of multiple spacers, reducing production times by up to 50%. The machine is equipped with four opposing belts driven by brushless motors and mechanical movements on skids, enabling the automatic advancement of the spacer. After positioning the spacer at zero, the machine can mill spacers, including those requiring for the “English Style” profile processing. The versatility of the machine lies in its various processing possibilities. In automatic mode, by entering the external dimension data and the number of internal frames, the machine automatically calculates all the pieces, dividing the cuts to be made and providing the operator with the pieces to cut in sequence. In semi-automatic mode, if the frames are not evenly distributed, just enter the distances of the frames, and the machine will repeat the operations of the automatic phase, cutting spacers burr-free. Thanks to the sophisticated software created, it is possible to interconnect the machine with a management system in the client’s office, where upon loading production orders, the necessary data will be sent to the machine for the operator to take charge of the operations.

The operator can choose the order of execution of the pieces or follow the machine, which will automatically highlight the list and decrement the pieces executed until the completion of all orders. This saves the customer both time lost searching for lost or undelivered sheets and paper savings since everything will be displayed on the operator panel.

| Minimum Spacer Length: | 170 mm without spacer, 60 mm with spacer |

| Maximum Spacer Length: | 4000 mm (variable upon request) |

| Cutting Blades: | N°2 blades |

| Motorization: | Spindle motors with variable speed |

| Spacer Advancement (for ”English Style Processing): | N°4 opposing belts driven by brushless motors |

| Spacer Block System: | Automatic, controlled by brushless motor |

| Length: | 6500 mm + 1500 mm movable arm |

| Width: | 650 mm |

| Height: | 1500 mm |

| Weight: | 100 kg |

| Power Supply: | 220V 50Hz |

| Glass Transport Height: | +/- 960 mm |

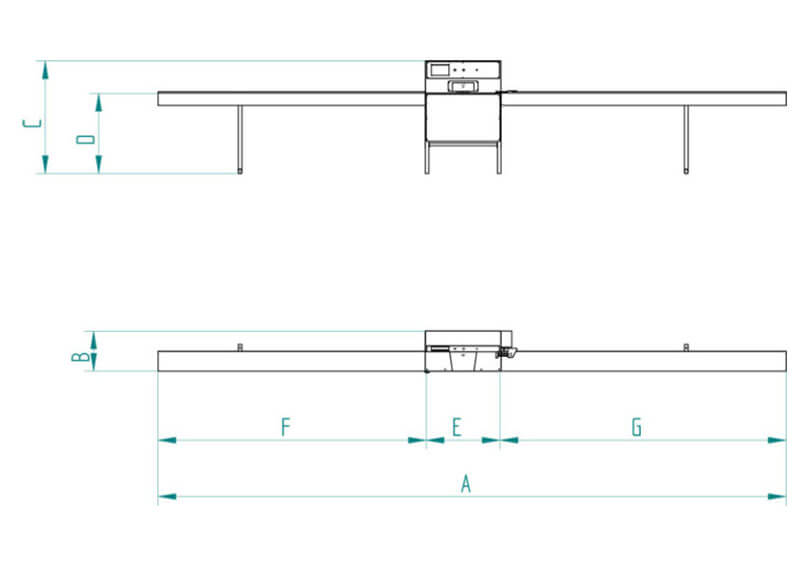

| DIMENSIONS | A | B | C | D | E | F | G |

| 7020 | 457 | 1260 | 920 | 820 | 3000 | 3200 |

Copyright © 2023 Itech Srl – C.F. and P.IVA 03587980289 – R.E.A. of PD 321966 – C.S. Euro 25,500.00 i.v.