The VEGA insulating glass production line has been developed to meet the needs of medium and large-sized glass companies. This line offers a comprehensive solution that adheres to the highest industry standards, with a daily production capacity of approximately 500 insulated glass units. The VEGA system is fully automated and includes a washing module, a pressing module, and a sealing robot. Each module can be purchased separately or as part of the complete line.

The vertical washing machine is versatile and can be used for various processes, including insulating glass production, grinding, beveling, drilling, CNC work centers, tempering, molding, and painting. Built entirely in stainless steel for greater durability, the glass washing machine features six Ø170 mm brushes, ensuring professional-level washing and drying for glass with thicknesses ranging from 3 mm to 50 mm, including low-emissivity (Low-E) glass.

The panel press is equipped with a profile alignment system and can be configured with or without a gas injection system, depending on customer needs. This press can handle double, triple, or quadruple glass with thicknesses up to 100 mm and can process shaped or offset panels, ensuring uniform pressing without deformation.

The VEGA sealing robot is designed to seal insulating glass panels after they have been assembled and pressed. It can seal double, triple, and quadruple glass with thicknesses up to 100 mm and a sealing depth of up to 45 mm. The robot is compatible with all major sealants on the market, ensuring high-quality sealing.

All machines in the VEGA line are fully automated and equipped with PLC and touch screen control panels, compatible with Industry 4.0 solutions. The lines can be customized with a wide range of options and configured for different workflow directions. They also support remote assistance. All controls operate at low voltage and comply with European safety standards, with safeguards to prevent access to dangerous parts. Our machinery is CE certified.

| Daily Production: | +/- 500 panels per day |

| Available Heights: | H1600 mm, H2000 mm, H2500 mm, H3210 mm |

| Minimum Glass Dimensions: | L400 mm x H200 mm |

| Maximum Glass Dimensions: | L5000 mm x H3210 mm |

| Minimum Thicknesses: | 3 mm |

| Maximum Thicknesses: | 100 mm |

| Gas Injection System: | Yes (can be built without gas on request) |

| Double / Triple / Quadruple Glass: | Yes (refer to individual machine specifications for details) |

| Shaped Glass: | Yes (refer to individual machine specifications for details) |

| Structural / Staggered Glass: | Yes (refer to individual machine specifications for details) |

| Maximum Load Capacity: | 500 kg/m linear |

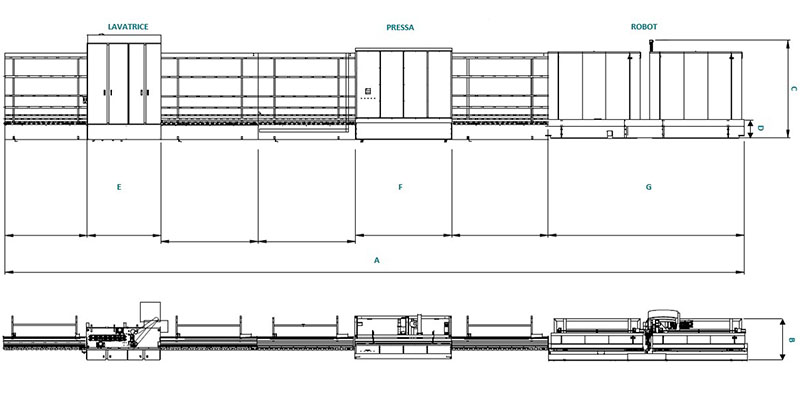

| DIMENSIONS | A | B | C | D | E | F | G |

| H1600 | 24000 | 1000 | 1600 | 650 | 8500 | 9000 | 6500 |

| H2000 | 24000 | 1000 | 2000 | 650 | 8500 | 9000 | 6500 |

| H2500 | 24000 | 1000 | 2500 | 650 | 8500 | 9000 | 6500 |

| H3210 | 37360 | 1200 | 3210 | 650 | 11020 | 15840 | 10500 |

Copyright © 2023 Itech Srl – C.F. and P.IVA 03587980289 – R.E.A. of PD 321966 – C.S. Euro 25,500.00 i.v.