Full description

The ITBA2500 Glass Rotating Corner Conveyor is designed to rotate 90 degrees and transport single glass panes or insulating glass units (IGUs) easily and safely. This machine is operated by independent systems and can interface with other machines on the line, allowing it to be positioned at any point in the IGU production process, whether it is at the edge processing phase, washing phase, pressing phase, or prior to sealing.

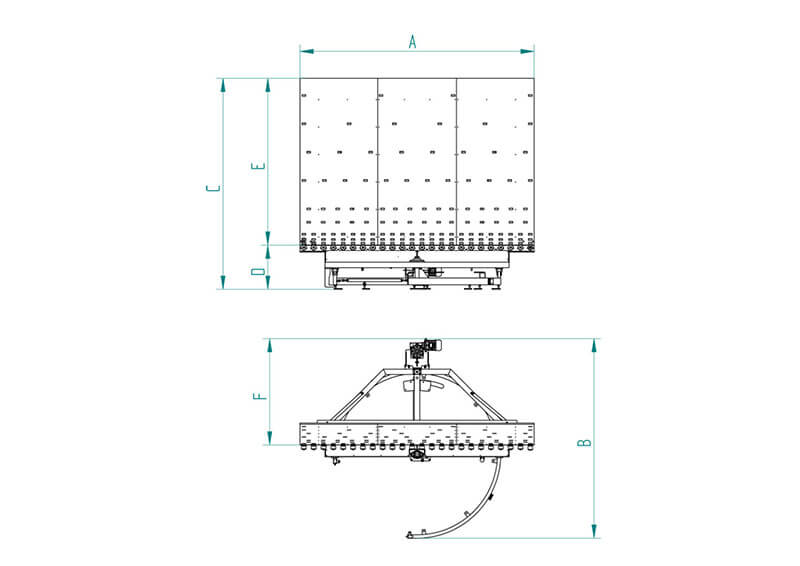

Our solution offers significant advantages in space optimization, enabling the addition of new units to the line even when there’s no parallel space to the existing line. The rotation of the corner conveyor is achieved through a belt system driven by a geared motor and wheels mounted on bearings. The surface of the conveyor features wheels with specially designed rings for glass handling, including specific ones for Low-E glass. Adaptable to the machines present in the line, the transfer speed can reach up to 40 meters per minute. The operator interface features a touch screen mounted on a separate post, designed for easy use. In addition to starting and monitoring the machine cycle, the operator can view the current status of the equipment, receive alarm notifications, and perform manual movements of the machine if needed.

Furthermore, the corner conveyor is equipped with a front radar system to detect human presence, ensuring maximum safety during rotation operations. All operator controls operate at low voltage and are equipped with safety protections in accordance with European regulations to prevent access to hazardous parts of the machine. Our machinery complies with CE certification and is equipped with mechanical barriers and gates at the back for operator safety.

Technical Data

Technical Characteristics

Gallery

Video