The VEGA single-head sealing robot is designed to seal insulating glass units (IGUs) with 90° angles, rounded corners, or shaped glass of various forms. This machine represents an innovative solution for medium to large-sized glass factories aiming to optimize the sealing process efficiency. Fully automated, it features electronic and mechanical systems controlled by multi-axis software managed by an industrial computer, enabling the sealing of double, triple, or staggered panels up to 100 mm thick.

The machine consists of 2/4 conveyors and a central axis. At the inlet conveyor of the sealer, an automatic reading system provides real-time data on the glass panels thickness and dimensions. Each conveyor includes two independent support and motorization systems, with a front section that adjusts to the width of the IGU and a rear section that moves vertically for structural glass production. At the entrance to the sealing head, there is a pneumatic system for closing the extruded product: the mixer (base component A and catalyst B). This system positions itself at the center of the spacer bar to be sealed via a 360° rotatable brushless motor axis. The ratio between the base component and the catalyst, the extrusion amount, and the pressure are controlled by the computer, which manages the single or double extrusion unit that can consist of two or four syringes moved proportionally by two or four brushless electric motors. The double extrusion unit is continuously fed, allowing uninterrupted extrusion of large volumes. Sealing occurs at an adjustable speed for each spacer section and each side of the glass. The sealing depth is automatically calculated up to 17 mm and can be manually set up to 45 mm of depth.

The process begins with the glass panel entering the thickness reading system, where the transport and vertical support bar adjust based on the readings. Subsequently, the IGU advances towards the sealing head, which positions itself at the center of the spacer bar and starts extrusion from the bottom entry corner. A probe, positioned on the head, detects the spacer bar depth and sends the data to the computer to perform a volumetric calculation to determine the extrusion amount. Each corner is finished with a finishing roller mounted on the head, constantly lubricated by an automatic system. Upon sealing the last side, the panel is transferred to the outlet conveyor, to be unloaded. Simultaneously, a new panel can enter, while for triple-glazed units, the operation is repeated on the second spacer.

The mixing ratio can be adjusted via the touchscreen according to the specific requirements of the sealant manufacturer. The machine can use any type of sealant available on the market, including polysulfide, silicone, or polyurethane-based sealants. For more aggressive materials, an external washing system with a tank and pump can be installed to clean the mixer at the end of the work cycle, prolonging its life and performance. The machine is equipped with analog and digital pressure gauges, alarm sensors to signal when the material in the drum is depleted, and multi-axis software compliant with the latest 4.0 technologies, managed by an industrial computer with a touchscreen operator interface. All controls operate at low voltage and are equipped with protections that comply with European regulations to prevent access to dangerous parts of the machine. Our machinery is CE certified.

The head is specifically designed for sized spacers, recommended for those with a width between 20 mm and 30 mm.

STRUCTURAL GLASS (ROBOT)By incorporating the structural system, staggered glass panels up to 100 mm per side can be sealed.

CUSTOMIZABLE HEADS FOR STAGGERED GLASSCustomizable heads are available with extrusion even at the staggered height, eliminating the need to manually smooth the entire staggered area.

ADDITIONAL SINGLE EXTRUSION SYSTEMExtrusion group with 2 syringes (1 component A, 1 component B) with feed pumps and a mixer to be added to the standard single extrusion system provided with the machine. Designed to allow sealing with two different materials at once.

ADDITIONAL DOUBLE EXTRUSION SYSTEMExtrusion group with 4 syringes (2 component A, 2 component B) with feed pumps and a mixer to be added to the standard single extrusion system provided with the machine. “JUMBO SERIES COMES STANDARD WITH THE DOUBLE EXTRUSION SYSTEM”

GLASS THICKNESS DETECTION SYSTEMThe non-invasive laser beam sensor is effective and high-performance in detecting thicknesses in double glazing, working excellently on all types of transparent glass.

LARGE GLASS PANELS UNLOAD SYSTEMBy adding cylinders and polyurethane wheels, the counter bars can be lowered to insert a clamp with opposed suction cups for unloading sealed glass panels. “THE JUMBO SERIES HAS THIS FEATURE ALREADY BUILT IN”

| Minimum Glass Size: | L380 mm x H180 mm |

| Maximum Glass Size: | L3000 mm x H2000 mm / H2500 mm “JUMBO” Series L5000 mm x H3210 mm (increased length on request) |

| Glass Thickness: | 12 mm – 60 mm (up to 100 mm upon request) |

| Maximum Sealing Depth: | 45mm (greater depth on request) |

| Spacer Thickness: | 6 mm – 24 mm (standard head) 20 mm – 30 mm (optional head for greater thicknesses) |

| Sealing Nozzle Positioning: | Automatic |

| Extruders: | N°1/2 for bi-component |

| Maximum Extrusion Speed: | 18 mt/min |

| Maximum Transport Speed: | 40 mt/min max |

| Triple Glass Sealing: | Yes |

| Shaped Glass Sealing: | Yes (with preset shapes or DXF file loading) |

| Structural Glass Sealing: | Yes (optional) |

| Large Glass Panels Unload System: | Yes (optional) |

| Type of Sealants: | polysulfide, silicone, or polyurethane |

| A-B Component Ratio: | electronically variable via touchscreen |

| Power Supply: | 10kW (variable based on the model) |

| Voltage: | 400 V – 50Hz3Ph + Ground+ Neutral |

| Maximum Load/Conveyor: | 1000Kg |

| Glass Transport Height: | 650 mm (+/-50mm) (variable height based on requests) |

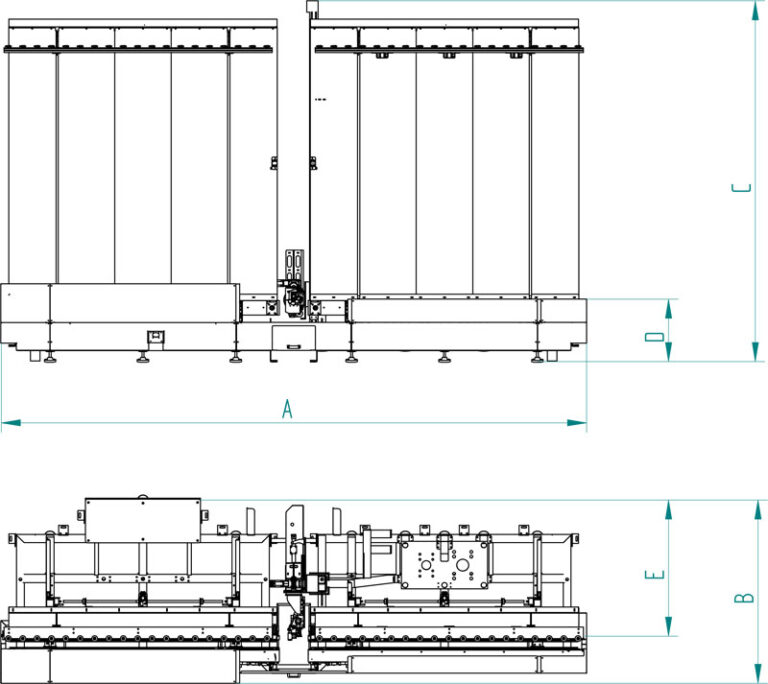

| DIMENSIONS | A | B | C | D | E |

| H2000 | 6250 | 2200 | 2500 | 500 | 1550 |

| H2500 | 6250 | 2200 | 3000 | 500 | 1550 |

| H3210 | 10500 | 2200 | 3400 | 500 | 1550 |

Copyright © 2023 Itech Srl – C.F. and P.IVA 03587980289 – R.E.A. of PD 321966 – C.S. Euro 25,500.00 i.v.