Our company

Craftsmanship, industrial reliability

The origins: from passion to business

In 1991, Mr. Andretta and his wife, Ms. Panizzon, founded a company dedicated to the design and installation of electrical systems and programming panels. Driven by their passion for technology and innovation in the glass industry, they broadened their path and founded ITECH Srl in 2001. This new company, oriented towards the design and production of tailor-made machinery for double glazing, began to serve glass factories in Veneto and Italy with innovative and customized solutions.

A family growth

Over the years, his children Matteo, Alessandro and Aurora joined the company, carrying on their father’s legacy and enriching the company with their skills. Matteo, with initial experience in the marble sector, moved on to dedicate himself to glass; Alessandro specializes in editing; Aurora, more recently, contributes to marketing and administration, strengthening ITECH’s presence in the market.

Over the years, constant research and development have allowed ITECH to expand beyond national borders, bringing its cutting-edge solutions to different areas of the world.

Commitment to the customer and Sustainability

ITECH is a company that places customer satisfaction at its centre, offering tailor-made solutions and effective and timely after-sales assistance. Strongly oriented towards sustainability, ITECH has chosen to operate in the glass sector, recognizing this material as an important contribution to the environment.

The values of a family business

ITECH, while maintaining a family dimension, stands out for its constant commitment to improving and personalizing services, aiming to build solid and long lasting relationships with its customers. We firmly believe that positive feedback and recommendations are the best advertising, a tangible sign of the quality and reliability that have always characterized us.

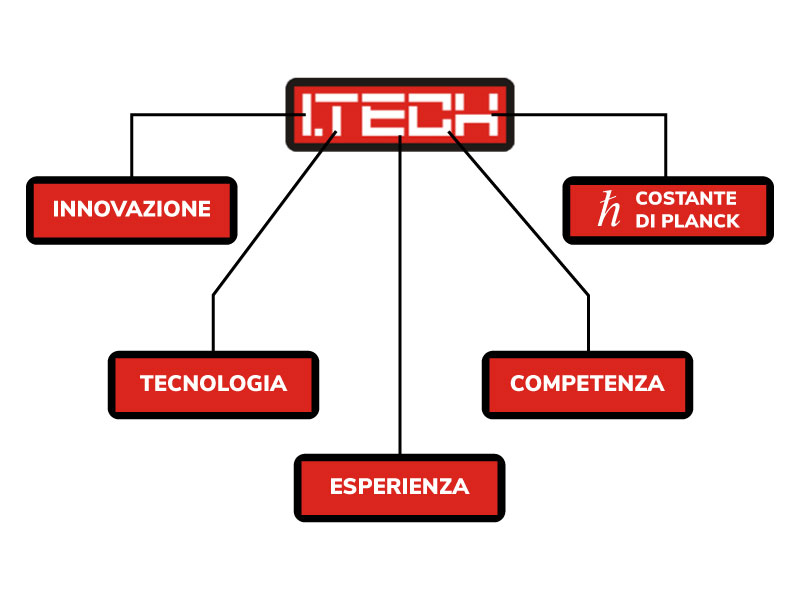

OUR MISSION

Maximum quality and high performance

I : Innovation: We constantly explore new ideas and cutting-edge solutions, offering an environment that fosters creativity and anticipates the needs of our customers.

T : Technology: By integrating the most advanced technologies, we create products and services that meet the highest quality standards, ensuring a competitive advantage for our customers.

E : Experience: Thanks to a team of professionals with consolidated experience, we face challenges with confidence and guarantee excellent results.

C : Competence: Our team is constantly updated to maintain top-level technical expertise, ensuring maximum quality solutions.

ħ : Precision (Planck Constant): Precision is a central value for ITECH, as Planck’s constant is for quantum physics. Every detail is taken care of to offer impeccable results.

OUR STRENGTHS

Integrated solutions for success

- Reliability: Quality components and materials, entirely “Made in Italy” and easily available on the market.

- Customization: We develop tailor-made solutions to perfectly adapt to customer needs.

- Consultancy: We offer specific consultancy to optimize the production process, respecting the peculiarities of each company's reality.

- Training: We organize complete courses for the optimal use of our machinery, with detailed maintenance guidelines.

- Assistance: We provide constant support, both remotely and on site, to minimize interruptions and maximize efficiency.

- Warranty: Each machine is carefully tested before shipping, guaranteeing excellent durability and performance for at least 15 years.

- Credibility: For over 30 years, our history is made up of successes and satisfied customers, which testify to our competence and dedication.

OUR HISTORY

Itech Srl was founded thanks to the extensive experience of its founders in the glass industry.

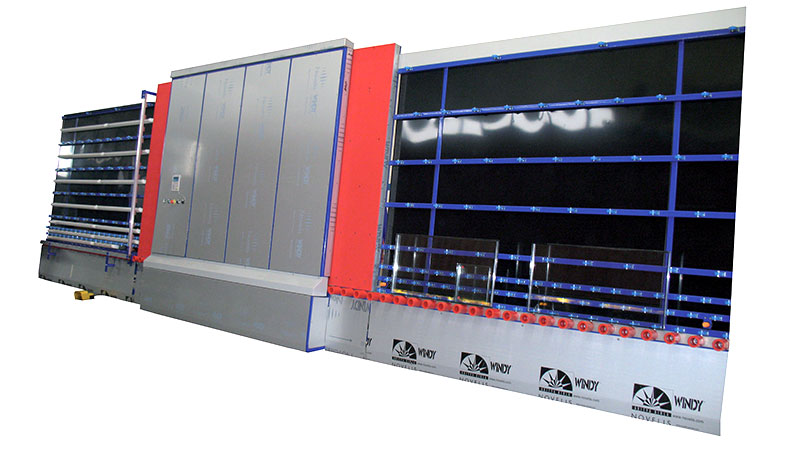

Itech launches its first insulated glass production line on the Italian market.

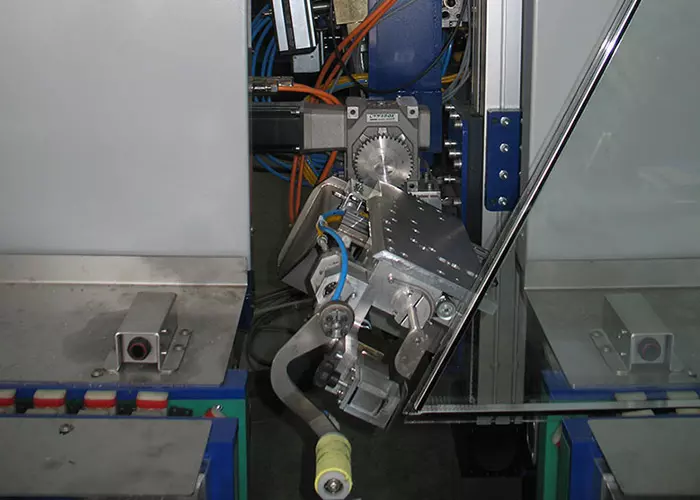

At the Vitrum trade fair, we unveiled the VEGA robot for automatic sealing of structural and shaped glass.

A new range of machines is designed and produced to speed up spacer processing.

Patented and introduced our new automatic in-press gas injection system.

First High-Productivity lines for large glass sheets (6000 x 3210 mm) with thicknesses up to 50 mm.

New automatic washing systems are introduced on Itech glass washing machines.

Development of a new sealing system on Itech robots.

The range of modular conveyors is expanded with the introduction of new models such as the Glass Rotating Corner Conveyor.

Our spacer processing machines had an update being more and more automated.

To meet market demands we studied and designed a new line for insulating glass, the Tauro series, to complement our proven Vega series.

Production of our first Tauro Series IG line, successfully sold in the European market.

To complete the Tauro series , we produced the first Tauro sealing robot.

Joining the profile processing machinery is the 2-blade spacer cutting machine for English style window profiles.

A new Itech's milestone, the realization of a 4mt long automatic press. Its strengths: High performance, innovation, and functionality.

The new patented APUS Vertical Dry Seaming Machine is presented on the market. Performing, Made in Italy, and compatible to other workstations.

Revisiting and restyling of the butyl machine in both automatic and semi-automatic versions.